Introduction

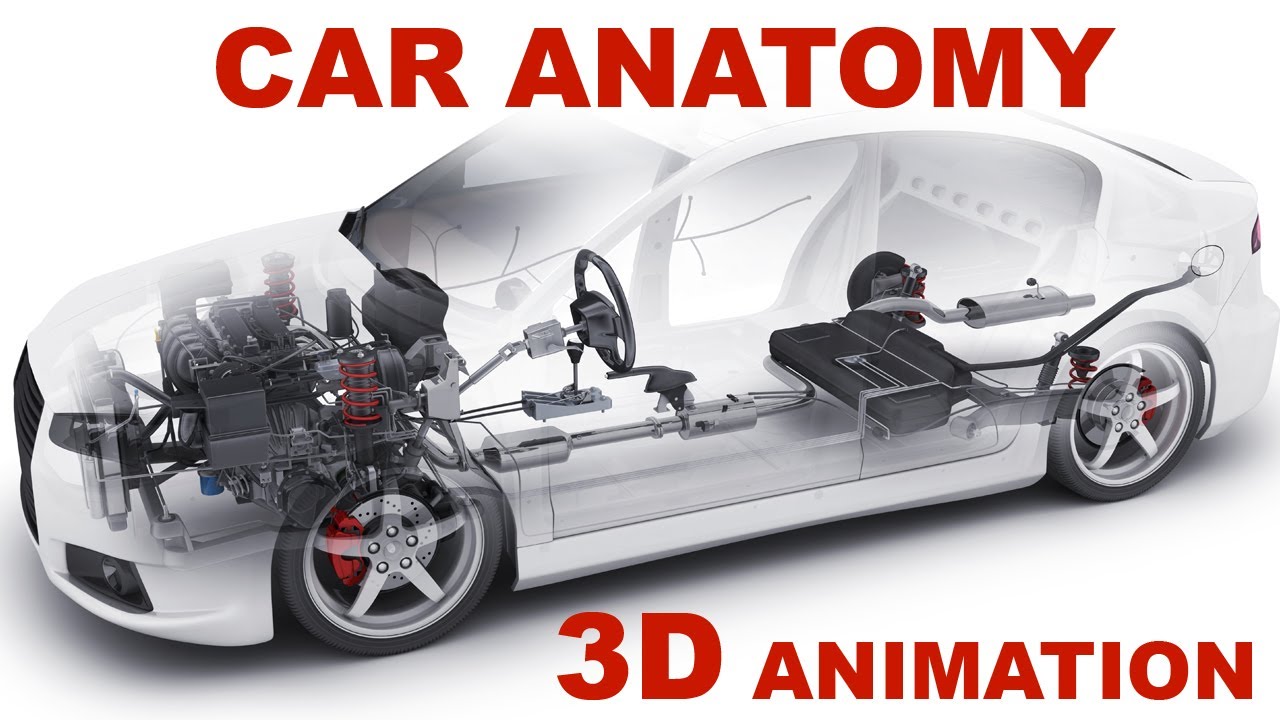

Auto mechanics troubleshooting includes figuring out and rectifying car troubles, guaranteeing they carry out appropriately and safely. Diagnosing commonplace issues requires a mix of technical information, hassle-solving talents, and systematic procedures. This text will uncover numerous commonplace points encountered in motors and discuss strategies to diagnose and treatment them appropriately.

Frequent Points in Auto Mechanics Troubleshooting

1. Engine Misfires

Engine misfires can stem from numerous components, consisting of defective spark plugs, ignition coils, gasoline injectors, or vacuum leaks. Diagnosing misfires usually contains scanning for error codes utilizing an OBD-II scanner, carrying out visible inspections, and performing assessments like cylinder stability or compression assessments to pinpoint the trigger accurately.

2. Beginning Issues

Beginning issues may result from a defective battery, alternator, starter motor, or ignition change. A scientific method involving checking battery voltage, inspecting connections, and attempting out parts may help diagnose the foundation goal. Voltage drop exams and starter draw assessments are diagnostic processes for figuring out starting issues.

3. Overheating

Automation overheating also can happen due to coolant leaks, malfunctioning thermostats, radiator troubles, or a defective water pump. Prognosis contains:

- Inspecting the cooling gadget for leaks.

- Checking coolant ranges and first-class.

- Making an attempt out the thermostat’s functionality.

- Be sure the radiator fan operates appropriately.

4. Brake Issues

Brake points, together with squealing noises, pulsating brake pedals, or diminished stopping power, steadily point out issues with brake pads, rotors, calipers, or hydraulic programs. Visible inspections, brake pad thickness measurements, and brake fluid analysis are elementary to diagnosing brake-related points appropriately.

5. Electrical System Malfunctions

Electrical system malfunctions can occur in various strategies, equivalent to dim lighting, malfunctioning equipment, or intermittent electrical failures. Diagnostic procedures embrace:

- Testing battery voltage.

- Analyzing fuses and relays.

- Checking wiring harnesses for hurt.

Theng multimeters to analyze electrical circuits.

- 6.

transmission Points

Transmission troubles, equivalent to slipping gears, troublesome shifting, or transmission fluid leaks, also can come up due to worn grasp plates, defective solenoids, or fluid contamination. Diagnosing transmission issues necessitates carrying out visible inspections, checking fluid tiers and circumstances, and performing diagnostic scans with specialised units.

7. Suspension and Steering Considerations

Suspension and steering troubles, like vibrations, uneven tire placed on, or steering wheel misalignment, may recommend troubles with shocks, struts, tie rods, or wheel bearings. Prognosis entails analyzing suspension components for placing on, performing alignment exams, and conducting avenue assessments to evaluate automotive dynamics precisely.

8. Exhaust System Defects

Exhaust machine defects, loud noises, excessive emissions, or leaks may additionally stem from damaged mufflers, catalytic converters, or exhaust pipes. Prognosis contains:

- Visually inspecting exhaust components.

- Carrying out leak assessments.

Theng diagnostic gear like exhaust gasoline analyzers to evaluate emissions.

- 9. Fu

l System Troubles

Gasoline system points like horrible gasoline monetary system, problem idling, or problem beginning may also outcome from clogged gasoline filters, malfunctioning gasoline pumps, or injector points. Diagnosing gasoline machine points entails inspecting gasoline stress, testing injectors for proper operation, and analyzing gasoline trims and the utilization of diagnostic tools.

Diagnostic Strategies in Auto Mechanics Troubleshooting

1. Visible Inspection

Visible inspections totally analyze car components for indicators of injury, hurt, or abnormalities. Inspecting hoses, belts, connectors, and fluid levels can usually monitor underlying points and handbook related diagnostic processes.

2. Diagnostic Scanning

Diagnostic scanning with OBD-II scanners permits technicians to retrieve fault codes saved in a car’s onboard pc machine. Decoding these codes offers treasured insights into potential points, aiding in targeted troubleshooting and restore.

3. Purposeful Testing

Purposeful testing contains assessing the operation of particular automotive programs or parts beneath numerous circumstances. Strategies along with voltage testing, stress testing, or resistance testing assist affirm the performance {of electrical}, hydraulic, or mechanical programs.

4. Take a look at Drive

Utilizing vehicles permits technicians to evaluate their efficiency, determine atypical behaviors, and mirror shopper complaints. Street assessments assist affirm the effectiveness of upkeep and be sure that identified issues have been successfully addressed.

5. Specialised Instruments and Tools

Using specialised gear and units, equivalent to digital multimeters, stress gauges, or smoke machines, enhances diagnostic accuracy and efficiency. These gear allow technicians to diploma essential parameters, carry out leak exams, and diagnose advanced troubles effectively.

6. Systematic Method

Adopting a scientific technique of troubleshooting entails following a logical sequence of diagnostic steps, removing capability causes methodically, and prioritizing obligations based mostly completely on their probability of resolving the problem. A structured method minimizes errors and facilitates inexperienced downside selections.

7. Stress Testing

Stress attempting out entails utilizing managed pressure on specific car programs and the cooling machine or the gasoline system to come across leaks or integrity points. As an illustration, a cooling system stress take a look at may help uncover leaks in hoses, radiators, or water pump seals by pressurizing the system with air or coolant and gazing any drop in pressure.

8. Smoke Testing

By introducing smoke into the gadget beneath slight stress, technicians can visually trace on the provide of leaks as smoke escapes, pinpointing areas of an issue for additional inspection or restore.

9. Oscilloscope Evaluation

Oscilloscope analysis makes use of an oscilloscope to measure and visualize real-time electrical alerts. This method is treasured for diagnosing sophisticated electrical troubles, along with irregular waveforms in sensor alerts or abnormalities in ignition gadget parts. Oscilloscope evaluation provides distinctive insights into the conduct {of electrical} circuits, helping in appropriate evaluation and troubleshooting.

10. Part Swapping

Part swapping entails briefly altering suspect components with acknowledged-top parts to find out if the issue persists. For instance, if an vehicle reveals indicators of a faulty ignition coil, swapping it with a functioning coil from every other automotive can help in affirming whether or not or not the coil is undoubtedly the supply of bother. Part swapping is a sensible diagnostic technique for separating defective parts and validating diagnoses.

11. Information Logging and Evaluation

Information logging includes recording and finding out car data, together with engine parameters, sensor readings, and general efficiency metrics. This technique lets technicians understand types, anomalies, or traits suggesting underlying troubles. By deciphering knowledge logs, technicians can diagnose intermittent points, display screen the system’s general efficiency, and optimize automotive operation appropriately.

12. Information-Based mostly Troubleshooting

Information-primarily based mostly troubleshooting is based on the experience and expertise of technicians to diagnose advanced or unusual troubles. Drawing upon data gathered on car buildings, components, and regular failure modes, technicians can rapidly determine functionality points and devise applicable diagnostic methods. Information-primarily based mostly troubleshooting enhances technical tools and diagnostic strategies, enhancing the effectivity and accuracy of trouble-fixing efforts.

Conclusion

Auto mechanics troubleshooting is a multifaceted technique that requires technical understanding, diagnostic skills, and sensible expertise. By understanding widespread vehicle issues and using applicable diagnostic methods, technicians can turn into conscious of points precisely and implement precious solutions. Steady coaching, staying updated with developments in automotive era, and honing diagnostic capabilities are important for achievement in car mechanics troubleshooting.

Leave a Reply

You must be logged in to post a comment.